Iron Ore Beneficiation & Pelletization (IoBP)

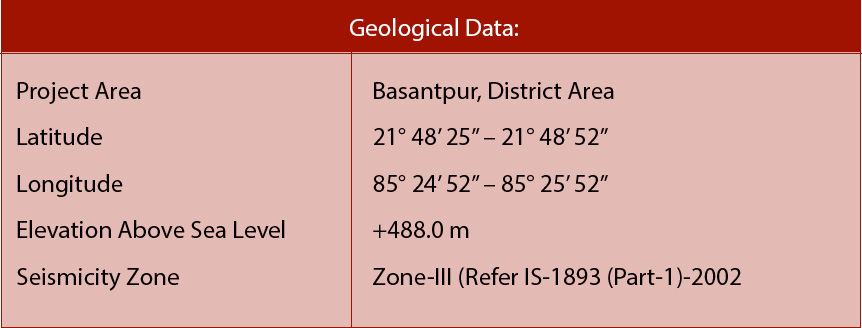

Essel Mining and Industries Limited (EMIL) is a pioneer in manufacturing of iron pellets through the distinguished and most compact circular Pelletization Technology (CPT). Known as Pro Minerals Private Limited (PMPL) became a division of EMIL in 2019. The plant is located in Basantpur, Keonjhar district of Odisha.

IoBP unit comprises of 1 million ton per annum capacity (MTPA) Iron Ore Beneficiation Plant based on the innovation of All Mineral GmbH, Germany and 1 MTPA capacity iron ore pelletization plant based on distinguished and flexible CPT.

A CPT plant provides producers with the flexibility to manufacture, just-in-time both high-quality blast furnace or direct reduction pellets with the respective chemical and mechanical properties. CPT plant functions on a circular design with a low building profile and small overall footprint. It was developed by Primetals Technologies Austria GmbH, a joint venture of Siemens AG and Mitsubishi.

BENEFICIATION PLANT:

The beneficiation process for a feed of 0-300 mm is designed based on the technology of Allmineral GmbH, Germany, which re-uses and recycles the process water to achieve a state of Zero Effluent Discharge. The plant is designed to utilize the low grade fines available in the nearby vicinity of grade 58-60 fe. The beneficiated ore is utilised as feed for DRI, Sinter and Pellet plant. Provision is also made to feed directly 0-20 mm raw material as plant feed.

Effluent from the iron ore beneficiation plant is treated in thickener and clarified water from the thickener overflow is recycled. Thickener underflow slurry is further sent to a filter press for solid-liquid separation. No slime pond is required but a small pond is provided in case of emergency. The solid waste released from the filter press is in the form of cakes which can be high stacked

PELLET PLANT:

EMIL’s pellet plant includes a circular induration furnace as its core component was developed by Primetal Technologies (PTAT) Austria GmbH. It is world’s first Circular Pellet Technology (CPT) for Pellet manufacturing and it is supplied by PTAT. A pioneer method of CPT our iron ore agglomeration facility is characterized by its exceptionally compact layout and light-weight development plan.

Contrary to straight-grate systems where one-half of the induration grate is returned empty to the charging station, the circular-grate design of a CPT plant means that the equipment utilization can be fully optimized. Not only can the required grate length for a given output be significantly reduced with CPT, energy costs are also reduced. EMIL is working to upgrade the plant capacity.

Village – Basantpur

Tehsil – Jhumpura, PS-Bamebari

District – Keonjhar (Orissa)

The PLANT SITE is located near the village Basantpur, in the state of Orissa, India